Demircan Plastik continues its services with years of quality assurance and experience. We produce all your parts by continuing to grow with innovative steps in the field. Our injection department is ready to serve all kinds of product needs of our customers with vertical and horizontal manufacturing options with different tonnage ranges. In our injection department, which works with many types of engineering materials, different and various molding methods are used.

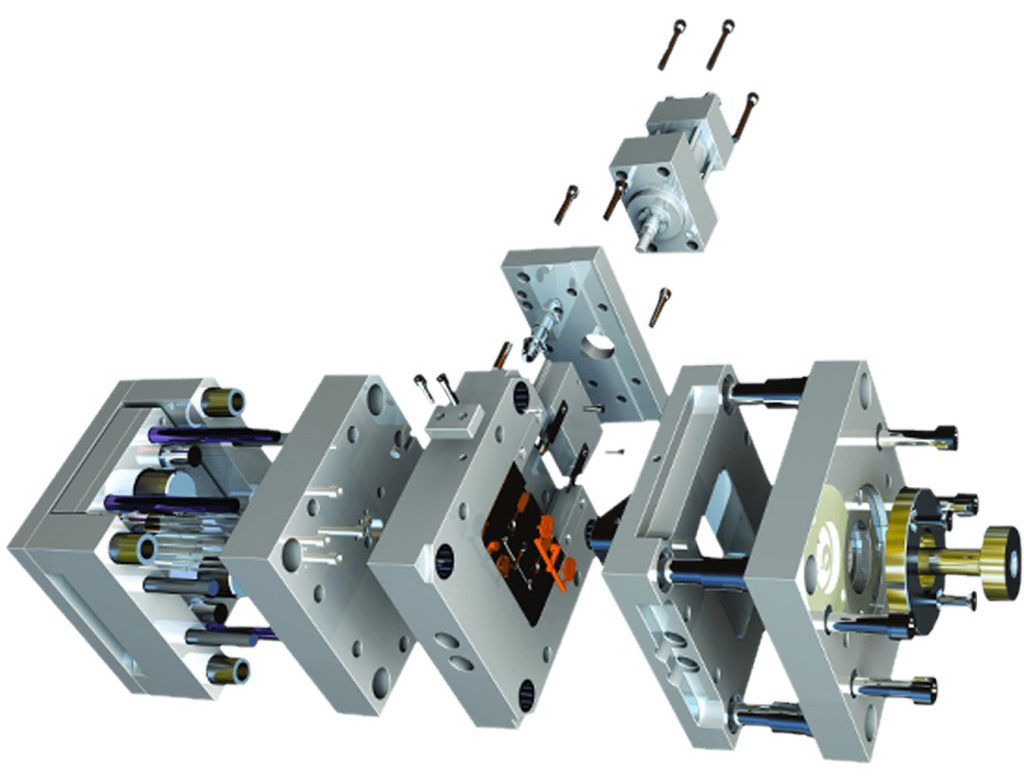

With the production of plastic parts, your needs in almost all sectors are met. The molds, which are produced in a special way in line with the demands of the customers with the orders from the customers, are also made ready for production in the injection part with a high quality standard. For this reason, you can easily supply the parts you need to your company and meet your sector needs.